Immersion Systems is proud to be a FCSI Corporate member – and the manufacturer of the new ImmersaFlex system. The system is a completely new category of equipment that ensures 100% process-controlled operations.

ImmersaFlex excels in the areas of fruit and vegetable washing and crisping (chilling), rapid food thawing, seafood de-glazing and thawing, and bagged food chilling. The system ensures food safety while significantly reducing labor, energy, water, and chemical usage. The system is unique as it uses “immersion technology” to create powerful wash action, agitation, and convection instead of pumps and manifolds.

Single footprint

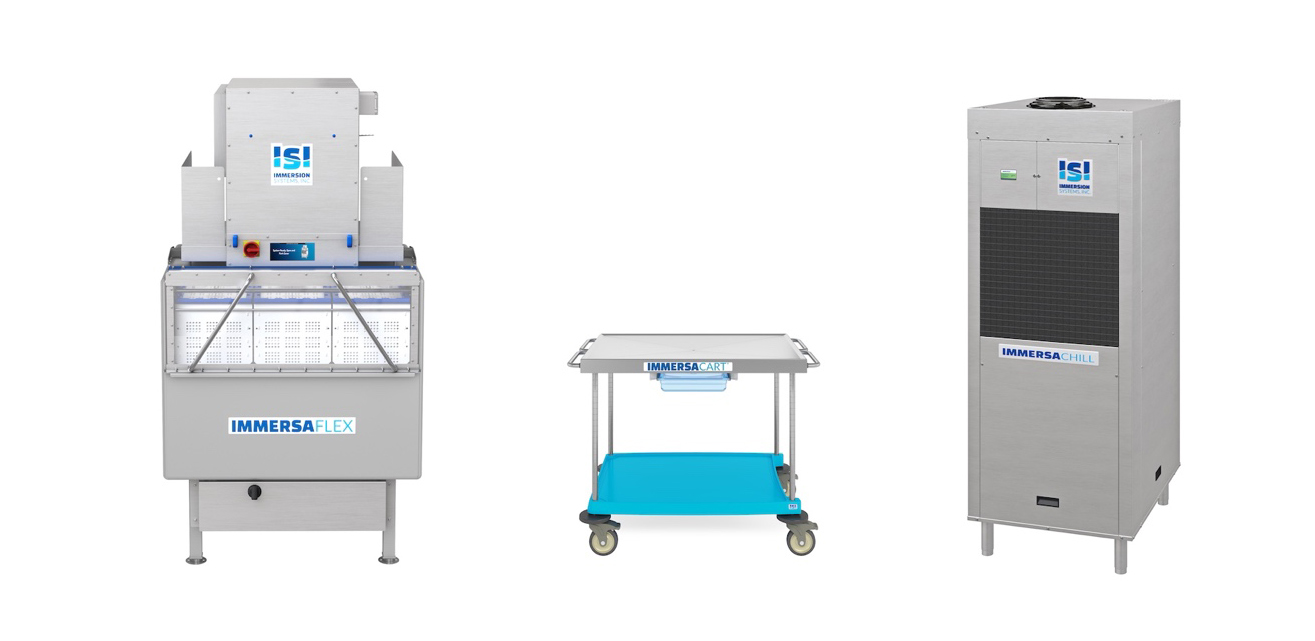

Now with one system, many processes can be performed in a single footprint. Multiple products that take different times can all be processed at the same time. The system features an easy-to-use touch screen for process selection and basket loading. Upon cycle completion, the system returns all the baskets to a Load/Unload position that is at an idea ergonomic height, making loading and unloading the system easy to perform, especially when used with our ImmersaCart system. When connected to the ImmersaChill system, 38°F chilled water can be delivered to the ImmersaFlex on an as needed basis for total temperature control.

A 100% automated, Clean-In-Place (CIP) process is required to switch from one process to another and when shutting the system down for the night. This CIP process can’t be skipped, even if the power to the system is cycled. The system operates near silently and uses less electric energy than a 200-watt light bulb. ImmersaFlex can operate on 110 or 220V single phase power at either 50 or 60Hz.

With three standard system sizes to choose from, Immersion Systems has just the right system for your client’s foodservice operation.

Further details:

Please visit www.immersionsystems.com for additional information.