2024 was a strange year. Lots of optimism that AI, and large language models, Dall-e and Chat GPT and so on, would solve all our problems and make life easier, but now it seems that these helpful tools are running out of steam and it’s a case of ‘Watch this space for the next big thing’.

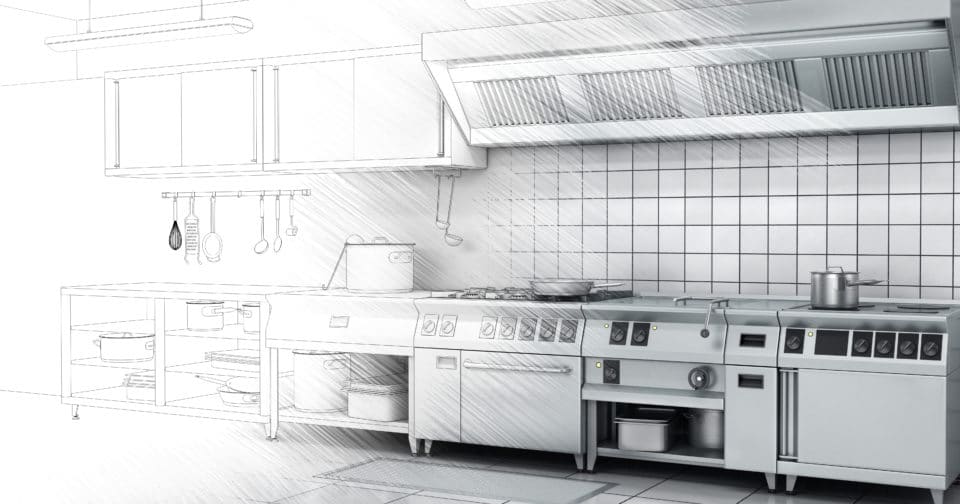

For the foodservice industry the big wake-up following the electric vehicle (EV) has been the ‘electric kitchen’ (EK). For some of us that’s been the case for over 20 years. Just as we’re discovering that an uninterrupted supply of electricity is going to get harder to achieve without burning more gas, we’re moving to demand that less gas is used as a cooking fuel: it’s a strange world.

And then there was robotics working their way into the kitchen. Well, generally not exactly In the kitchen, more in the front-of-house for the delivery of meals or making coffee; in both cases slower and with less personality than the staff the promoters claimed not to be replacing.

Even robots need to be trained

We have seen robots, ‘Cobots’ to be exact, applied to flipping hamburgers and dumping fries into the bin, but again from a speed and efficiency perspective, not as productively as well-trained staff. I know, you’ll tell me that you can’t get staff – let alone trained staff – to do the job, which is certainly true in some places but not everywhere: and remember even a robot has to be trained. However, if the facilities, as a work environment, are well designed by a FCSI designer, and the operation of the facility developed by a FCSI management consultant, it will make the difference between a good place to work and to keep good workers, and the rest.

But are robots the answer to these problems? I think the future is both maintaining skills-based personal service approach, with all the limitations that implies, and automation. Automation should not be confused with robotics, which can be part of an automated system. But an automated system can exist without robots, in the sense they are currently applied.

Over the past couple of couple of years, we have seen the development of automated systems that achieve single purpose activities, such as salad bowl filling, where high volumes of repetitive tasks are replaced; and that makes good sense. More recently this year we are now starting to see more flexible automated cooking and preparation equipment coming out of Asia which is much more achievable for the average restaurant business.

Custom made – and automated

At this year’s Food & Hotel Asia HoReCa (FHA) exhibition in Singapore it was interesting to see a significant number of examples of each: custom made island chef’s ranges and automated cooking equipment, which goes to my point, the foodservice industry needs both to deliver what is expected of it.

It is at the intersection where a high-volume production kitchen effectively becomes a food processor, that automation first finds its natural place. Over 10 years ago I designed a production kitchen producing over 20,000 meals a day, in other words over 5 tons of ingredients converted into meals every day of the week.

We didn’t use Combi steamers or Blast chillers but did use pumps, conveyors, automated filling and bagging machines, able to run the hot production with two or three staff over two shifts. Automation for the foreseeable future in the foodservice industry will not be single complex machines, but a series of technologies and equipment designed to enable a flexible production outcome. This requires foodservice consultants to become much more engaged with the general automation industry worldwide to understand the possibilities.

Why ‘environment’ really means efficiency

The other big story for 2024 has been the environment. To some that means eliminating the use of fossil fuels. Not to me. My view can be summed up as making everything we do as efficiently as possible. Making electricity efficiently using the most effective technologies, thereby minimizing harm to the environment: “Do no harm” should be the core efficiency mantra. Efficiently making meals: that is, eliminating waste: energy, labor, ingredients, supplies, chemicals etc, all done as efficiently as possible has the possibility of achieving the same result for the planet.

After many years of promoting and encouraging, with others, better waste management practices, we are now starting to see the issue becoming mainstream in the foodservice industry. Measure and produce less and throw away less! Convert food waste to something useful; replace packaging with recyclable containers; replace harmful chemicals with natural green chemicals, and so on. All have been possible for decades, but only recently discovered by the mainstream industry. Better late than never.

In 2025 I start my life in Portugal and look forward to joining the FCSI EAME membership in promoting the message of professionalism in our industry. Is this retirement? No. A change for a new perspective on life and living, writing and helping others achieve their goals.

I hope you had a great holiday season and wishing you successfully manage the challenges of 2025.

Tim Smallwood FFCSI