Production Kitchen, Central Kitchen and Central Production Unit (CPU) are all three descriptions used to describe the process of partially or fully centralizing or separating the production of food from the point of service with the aim of achieving the various benefits of the processing of volume rather than individual batch. This currently is as far as most foodservice businesses get to achieving the performance of Industry 2.0.

For over a decade I have had the pleasure of working with a range of foodservice operators both directly and through running workshops on the approach to developing their production kitchen proposals. Workshops involved those involved in a wide range and type of operation from multi-unit restaurants, healthcare and even casinos. Each having decided that they had reached a critical mass sufficient to support the benefit of centralizing and standardizing a proportion; or all, of their production.

Of course, there is a significant difference in the requirements for each of these entities, but the anticipated outcome is the same, and therefore the approach to developing the solution will always start the same way: to decide the point in the meal production process that there is a benefit in centralizing that production.

Sketching out a process flow diagram is an effective way of describing how the existing operation works and even showing where some of the operations diverge from a standard preferred approach. This can be as a result of location, local rules or property limitations, but in all cases by identifying these deviations from the preferred operation it is possible to effectively: 1) define the most effective stage to centralize, and 2) improve standardisation through the chain.

There will be a number of reasons for considering centralizing part or all of the production and these may not always be primarily financial. In some cases, it can be lack of or the reliability of suitable staff or difficulty in getting reliable deliveries of supplies at locations or even limitation on space or energy supply at some locations. Whatever the reason, they will help inform the point at which the production is centralized. However, at all times the issue and cost of logistics must be at the forefront of thinking. Within a large single complex such as a casino this may not be an issue but in a widely distributed multi-unit chain operation it can be the first question that needs to be resolved in the positive before proceeding further.

Having confirmed that the logistics can be made to work, applying the main reasons for centralizing production: cost saving, availability of staff etc, the process flow chart can be used to decide the optimum point in the production process for centralizing. This might be as simple as centralizing the purchasing of supplies and breaking them down for individual locations to gain the benefit of standardization and bulk purchasing. In this case the operation becomes a central commissary operation with no actual food preparation or cooking taking place. At the other end of the possibilities, the central kitchen may prepare fully finished meals ready for final heating (if required) and service as in the case of airline meals. However as in this case, the issue of efficiency taking precedence over quality is nearly always an issue.

The perfect spot will be somewhere in between and again is dependent on the motivation for centralizing production; just to take a few:

Lack of skilled staff:

If it is the availability of staff maintaining the quality of the finished meal then the cut off point for the central production will be as close to the point of plating and service as possible. This may involve sous-vide and certainly chilling prepared/finished meal components; in fact, becoming a food bank storing ready to finish meals.

Lack of available kitchen staff:

In this case it is assumed that the operating units have competent chef and cooks able to maintain the quality of the finished meal but problems with unreliable kitchen support staff. The central production kitchen would then be preparing the mis-en place and other meal parts as well as breaking down the bulk packaged supplies to minimise the amount of waste being handled to minimise the need for support staff.

Lack of space

Great location but very cramped back of house space, which to increase would reduce the dining space. The solution would be very much as for the lack of support staff but also may involve partial cooking such as stock preparation as well as the basic mis-en-place in the production kitchen.

Energy limitations

Similar to the basic limitations on staff availability, it will be the energy required to finish the meal at a quality ready for service that is essential with all the preceding processes needing to be undertaken off-site, including dishes based on bulk cooking, blanching, etc, being undertaken in the central production kitchen.

Availability of supplies

There may be situations where a location is not supported by a reliable foodservice ingredients and supplies distributor. In this case the issue is overcome by centralizing the purchase of these supplies and achieving the cost benefit of bulk purchasing; as well as overcoming any of the other limitations. In all cases the benefit of centralizing the purchasing and distribution of supplies in all of the options extends to more than just bulk buying cost, to include waste management as well as food safety, by removing all contaminated boxes before the supplies are taken into food preparation areas.

Logistics

As can be seen, in all cases the efficiency and cost of logistics becomes a critical aspect to the viability of a centralized production system. In all cases the lowest cost will be the availability of a commercial refrigerated distribution network able to cover the outlets or restaurants that will determine the viability because the cost benefit of centralizing production will be offset by the cost of distribution. In the event that refrigerated distribution is not available, the use of insulated shipping modules can enable the distribution by normal freight at a lower cost than refrigerated transport.

The alternative, if the volume or number and relative location of outlets justifies, would be operating the logistics through contracting individual refrigerated vehicle owner drivers for regular distribution deliveries. Or in the most extreme case would be for the production kitchen to operate vehicles and drivers completely in-house: which would be an extreme decision for any catering business.

Each of these factors for considering the move to a centralized production will determine where the line is drawn in the operating workflow diagram to show what is centrally provided and what is locally delivered and then identifying what facilities and equipment are required each side of the line.

Having determined that the cost of logistics is viable, the next step is to identify the facilities required to resolve the issues that have prompted the move to centralize production and changes to the existing facilities in addition to the capital cost of establishing the production kitchen and the overall investment, and of course where will AI fit into this new model of service and move to Industry 3.0.

Coming up next:

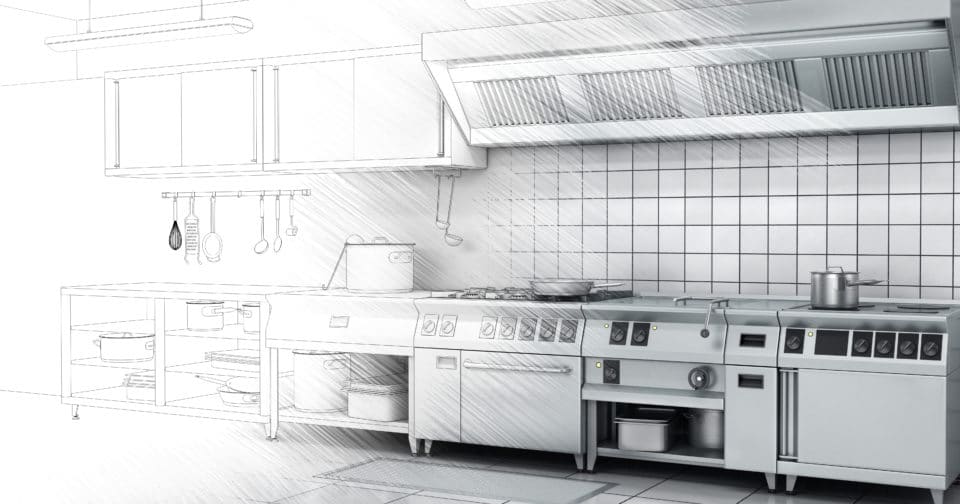

Facilities, systems and equipment available for the production kitchen and matching it with the Finishing Kitchen facilities.

Tim Smallwood FFCSI