An hour’s drive outside Brussels lies the city of Namur, capital of the French-speaking part of Belgium (Wallonia). The city authorities wanted to create a fully functional catering space at CPAS Namur with the capacity to make up to 2,500 meals a day as part of its social welfare offering. In an area that had no existing central kitchen facilities, the project was ambitious from the start.

“The idea was, to begin with, a kitchen that would cater for the most vulnerable people in the region – those in residential care homes, as well as people who needed to have meals provided with a home-delivery service,” says Vincent Sechehaye, designer and project manager at ERM Project, who consulted on the venture. The kitchen will also deliver to schools, with a specific aim to provide hot school meals for children, particularly those from the most vulnerable backgrounds.

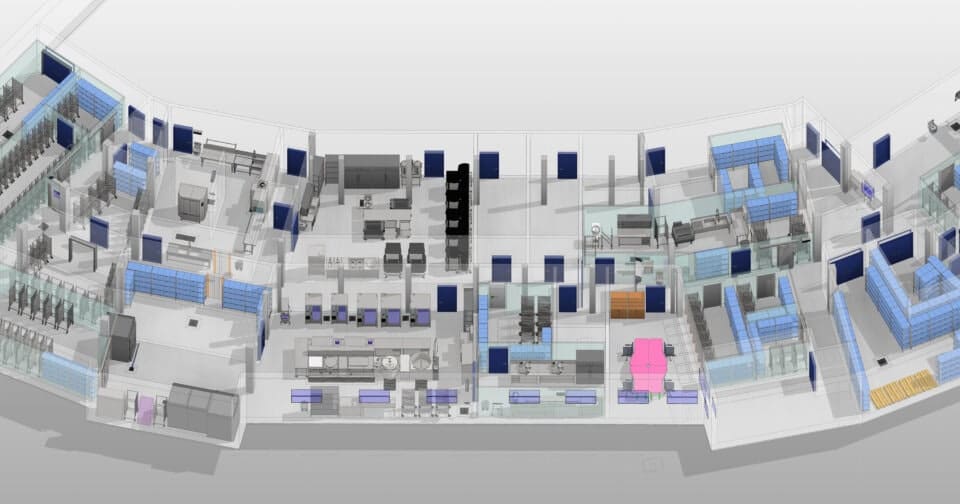

Sechehaye first began working with architects AAU on the central kitchen around 2014, discussing the size of kitchen that would be needed and how to approach the task. As the project developed, the number of care homes and other clients to be served increased; what had begun as a 150 sq m kitchen eventually became a huge 1,000 sq m space.

Integrating existing architecture

The workspace was to be designed within a pre-existing building – one that had not been planned with large-scale catering in mind. “We were not able to change the architecture, so we had to use what we had,” says Sechehaye. “There were a lot of columns around the building that we could not remove or displace, so we had to integrate these into the design.”

The overall shape of the building was not, Sechehaye admits, one that he would have chosen. Built in a long, narrow and slightly curved shape, it came with access challenges both for deliveries and personnel. “Everything and everyone had to enter and leave from one end of the building,” he explains.

Today, those columns have been integrated into storage and separating walls, so for the most part they form an invisible element of the kitchen’s structural framework. The interior of the building is planned around one long corridor, with doors on either side leading to the different preparation, cooking and storage spaces. External entrances and exits have been modified to allow for a better flow of people and deliveries, both to and from the kitchens.

Olivier Haution, a manager in the central kitchen, admits that he and the team had some concerns as the project began to take shape. “We were worried about the space we would have; the kitchens are built along and either side of this long corridor, and we thought we might lose a lot of time walking from one end to another,” he says.

In reality, though, the design of the kitchen, with its ample storage space and modern equipment, has had the opposite effect, allowing the team to optimize their time and manage their workload to fit in with an evolving demand for the kitchen’s services. “We’ve gone from prehistoric conditions to modernity,” he says. “Everyone works much better now, and the food we cook is of a higher quality, too.”

Dene Rachid FCSI, technical director at ERM Project, says: “In terms of the quantity of meals that can be produced, or the process used, the project was not out of the ordinary. However, our team came relatively late to the project, and in spite of architectural constraints linked to an unanticipated expansion of the kitchen spaces, and the resulting technical complications, we were able to deliver the project entirely within the parameters given – both in terms of budget and timing.”

Energy and labor efficiencies

Equipment was chosen to fit in with budget constraints, while providing value for money, and energy-saving formed an integral part of the plan. “The ventilated ceiling reduces energy use and saves heating costs,” says Sechehaye. “In a kitchen like this, 30% to 40% of energy use is related to ventilation, so this efficient system will bring about real savings.”

The kitchen has had pasteurisation equipment and an industrial heat sealer installed, both of which allow for increased storage times. In addition, large CO2 cold storage chambers provide energy-efficient space to stock prepared food. All of this equipment means staff can work on preparing large quantities in advance, cooking high numbers of meals one day and packaging the next. Meals can then be stored within the kitchen’s own spaces before being delivered to clients in their homes or residential care facilities on the necessary days.

“Extending shelf life in this way will mean we can manage our productivity time so that we no longer work on weekends or public holidays,” says Haution. That will mean fewer working hours, which will have a positive impact on budget.

The new set-up allows the team to produce quantities of hot meals for delivery to those establishments that have no kitchens on site, and chilled meals where heating can be done immediately before service. And, explains Haution, they are better equipped now to serve the food their clients enjoy. “We have the capacity to cook large quantities in a traditional way,” he says.

Catering for young and old

Schools will also benefit from the new kitchens. The current plan is to provide around 2,000 local school children with hot soups made from local produce every day, to ensure a good nutritional balance for those who may be lacking access to fresh fruit and vegetables.

Today, Haution’s teams make enough for around 800 meals a day, a number that will increase to 1,600 in September when production of school meals begins in earnest. To optimize time and equipment, the kitchens will cook the same meals for all customers – from children through to the elderly. Those dishes that older people often like, but children tend to turn their noses up at, will be saved for days when the schools are not receiving deliveries (Wednesdays and weekends). On days when the teams cook for schools as well as residential homes, menus will favor the types of foods that are equally likely to be eaten and enjoyed by children.

The uses for the kitchen are evolving all the time, and so far the project is a great success.

“We are really happy with the way the kitchen operates,” says Haution. “We have the capacity to double our production, and we have all the storage we need to ensure we can stockpile food that has been cooked in advance.”

Indeed, says Sechehaye: “The facilities have been designed to cater for up to around 2,500 meals in total.”

Sandra Haurant