More energy efficient, faster, cleaner, with lower water consumption, and easier to use – plus, the machine and the wash programmes can be customised to ensure the best possible results, whatever the local conditions and whatever is being washed. Winterhalter says its PT Series, the all-new range of passthrough warewashers, delivers a new level of washing efficiency.

The PT is the market’s first passthrough with energy-saving heat exchange technology fitted as standard. The system extracts energy from the waste water, using it to heat up the incoming cold water supply, reducing energy costs by up to 10%.

The PT Series also features an energy control system that speeds up the washing process, increasing rack capacity per hour by 28% and reducing heat-up time by 50%. It works by making best use of the available power – for example, by prioritising heating of water, it ensures the boiler has maximum power when it needs it. However, in standby mode it allows the boiler temperature to reduce to minimise energy consumption. The speed of the system means the PT is ready for action faster than conventional passthroughs, allowing back-to-back rack washing, which will be a huge bonus for busy kitchens in peak times.

The PT is the first passthrough that can be truly customised to each site’s requirements and local conditions. The installation engineer can adjust the machine to take account of everything from the type of food on the menu to the hardness of the water and calibrate the machine accordingly.

The PT’s VarioPower feature allows the operator to quickly optimise the programme to suit the delicacy or dirtiness of the wash items. All staff have to do is push the relevant pictogram on the control panel to select the wash they want. VarioPower adjusts pressure, temperature, time, detergent and rinse aid to ensure perfect results are guaranteed, even with stubborn soiling.

Other headline features include the patented ‘full jet’ filtration system which, in conjunction with Winterhalter’s established Mediamat filter, constantly cleans the washwater to ensure it is clear of impurities. Meanwhile a clouding sensor in the wash pump monitors the washwater, taking only as much replenishment water as is required. These sophisticated filtration and monitoring systems enhance the efficient discharge of food residues by up to 35%, compared to previous models, further minimising water consumption and delivering the best possible wash results.

The PT has elliptical wash arms whose jets are individually formed, sized, positioned and angled to deliver 100% coverage, even into the wash cabinet corners, and achieve high pressure washing of heavily soiled items. In combination with the new VarioPower and advanced filtration system, the wash arms improve the brilliance of cleaning results by up to 29%.

The new PT is extremely easy to use, whatever the operator’s first language: clear touch-activated pictograms set the program in motion. Visual and audio alarms let staff know instantly if there are any problems, such as a blocked wash field or lack of detergent.

“In warewashing there are three key aspirations: better results, more quickly, at a lower cost,” says Stephen Kinkead, managing director of WinterhalterUK. “What’s ground-breaking about the PT is its ability to deliver all of them at once. This is truly innovative technology that delivers major benefits to operators.”

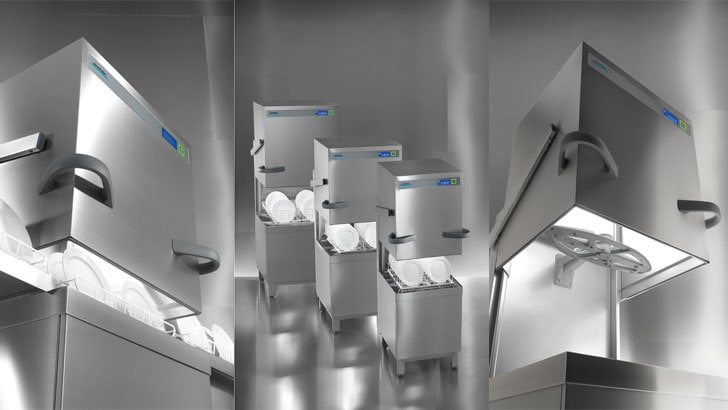

Initially there are two machines in the range, the PT-M (medium) and the PT-L (large). Their theoretical capacity is up to 77 racks per hour for glasswashing and 72 per hour for dishwashing.

Find out more about the new PT at www.winterhalter.biz/fileadmin/PT-Scout/?UK_en

Foodservice Consultant is not responsible for the content of company product announcements